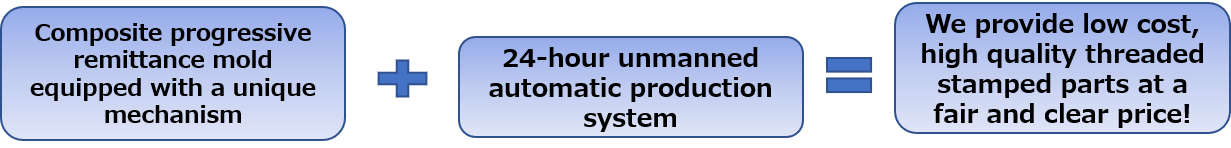

Description

Absolute confidence in cost!

VE the current product by pressed parts with screws !!

- All-in-one completion of stamped parts with tapping in a compound progressive remittance mold!

- Stable quality and cost down!

- It is possible to manufacture your own compound progressive remittance mold at the same cost as the conventional progressive remittance mold

- Tap processing ability:M1~M6!

VE proposal results

Achieve various processing in the progressive remittance mold

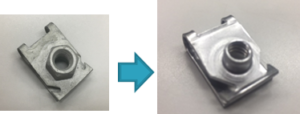

Clip nut for car headlights

The parts that crimped the hexagon nut are integrated in the press die.

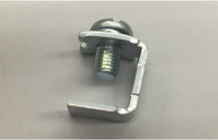

Automotive board terminal

At the design stage, the parts that were planed to be joined with the cut cylindrical parts were integrated by drawing. Furthermore, by making the tip of screw parts into a bag-shape, problem due to dropping of contamination are prevented.

Board terminal screw

Male screws are manually inserted into the press-processed terminal block, and the ones that have been crimped are batch-processed in the press die.

Antenna nut for mobile phones

Both cost reduction and quality improvement are achieved by batch processing in the press die, which was conventionally produced by die casting.